Green Refrigerants in India: R290, R600a, HFO, Natural Refrigerants & the Kigali Amendment

Cooling is Heating Up

Step into any supermarket in India, and you’ll feel it instantly — chilled Corridors lined with fresh produce, cold drinks, and frozen foods. Behind the cool comfort lies a not-so-cool fact: traditional refrigerants are some of the biggest contributors to global warming. The very chemicals that keep food fresh, vaccines safe, and rooms comfortable are heating up the planet.

But here’s the exciting twist: a refrigerant revolution is underway. From R290 in air conditioners to R600a refrigerant in refrigerators, from HFO-driven chillers to ammonia and CO₂ in warehouses, India’s cold chain is beginning to run on climate‑friendly cooling. And at the heart of this shift is the Kigali Amendment India commitment — a global agreement shaping the future of every exhibitor and visitor in the cold chain industry.

Why All Eyes Are on R290

R290 (propane) has emerged as a leading eco‑friendly refrigerant. With a global warming potential (GWP) of only 3, it is thousands of times lower than conventional HFCs such as R‑410A. This makes it one of the most climate‑benign options currently available.

India has been an early mover in this space. Godrej Appliances pioneered the use of R290 in residential air conditioners, establishing a benchmark for sustainable cooling on the global stage. The application of propane is now gradually expanding into small cold rooms, retail display cabinets, and supermarket refrigeration equipment. For cold chain operators, this transition translates into systems that not only reduce environmental impact but also deliver improved energy efficiency and lower operating costs.

R600a Refrigerant: Quietly Powering Your Fridge

R600a (isobutane) has become the standard refrigerant in domestic refrigeration. In recent years, nearly all leading manufacturers — including LG, Samsung, Whirlpool, and Haier — have transitioned their product portfolios to R600a.

The rationale behind this shift is clear. R600a offers an extremely low global warming potential (GWP) while simultaneously enhancing compressor efficiency, which translates into significant reductions in household energy consumption. When scaled to the national level, this transition prevents the release of millions of tonnes of greenhouse gas emissions annually.

For the broader cold chain industry, the success of R600a illustrates that mass-scale adoption of natural refrigerants is both practical and commercially viable.

HFO Refrigerants: The Bridge for Bigger Systems

When it comes to large warehouses, distribution hubs, or commercial HVAC, hydrocarbons like R290 or R600a may not always be practical due to flammability and capacity constraints. Enter the HFO refrigerants (Hydrofluoroolefins).

Solutions like R‑1234yf and R‑32 blends bring big advantages:

- GWP under 1–10 in many cases (compared to thousands for HFCs).

- Safer handling in large-scale systems.

- Compatibility with existing equipment with minimal modifications.

In India, companies like Daikin, Carrier, and Bluestar are already introducing HFO‑based chillers. Exhibitors showcasing HFO systems tap into demand for compliance‑ready technology. Visitors see them as a smart transition on the way to a fully natural refrigerant future.

Natural Refrigerants for the Cold Chain Backbone

Ask any old‑timer in India’s cold chain, and they’ll tell you: ammonia (R‑717) has been the backbone of large cold storage for decades. It’s efficient, cheap, and has zero GWP. Today, improved safety features make ammonia systems compact and reliable, even for modern facilities.

At the same time, CO₂ (R‑744) is entering the stage. Used worldwide in supermarkets and deep freeze systems, CO₂ is gradually finding its way into Indian food logistics. Its ability to operate efficiently at both chilling and freezing temperatures makes it attractive for multi‑temperature cold stores.

The Kigali Amendment India: Why Transition Isn’t Optional

None of this is optional. Under the Kigali Amendment India commitments, the country will begin phasing down high‑GWP HFC refrigerants in 2028, with a goal of 85% reduction by 2047.

To make that happen, the Indian government has laid the groundwork:

- India Cooling Action Plan (ICAP): a blueprint for efficiency and refrigerant transition.

- HCFC Phase‑Out Program: already nudging industry towards alternatives.

- Updated BIS standards: making sure tech like R290, R600a, and HFO refrigerants are safely implemented.

Future Outlook: Green Refrigerants as Growth Drivers

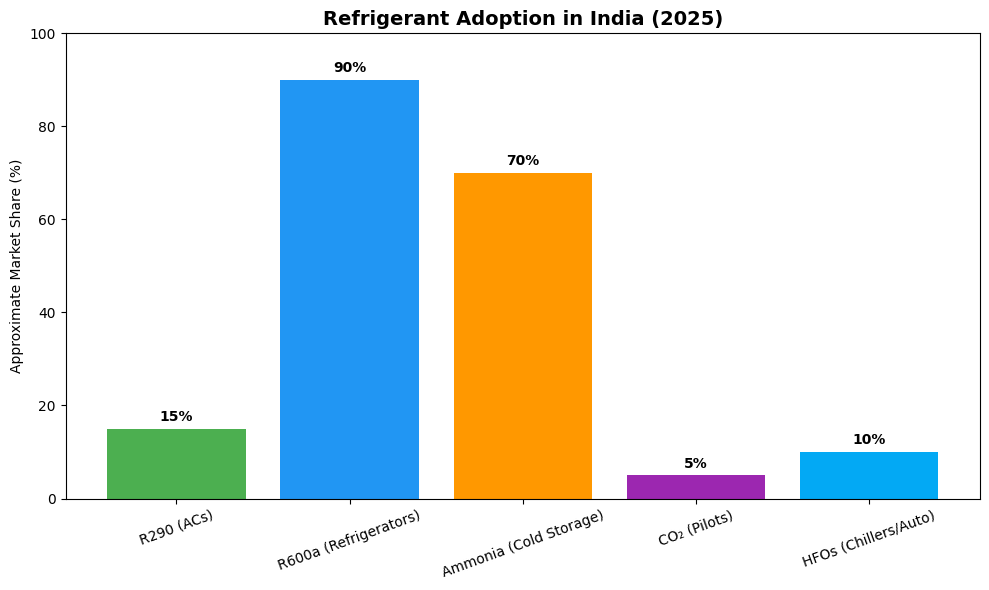

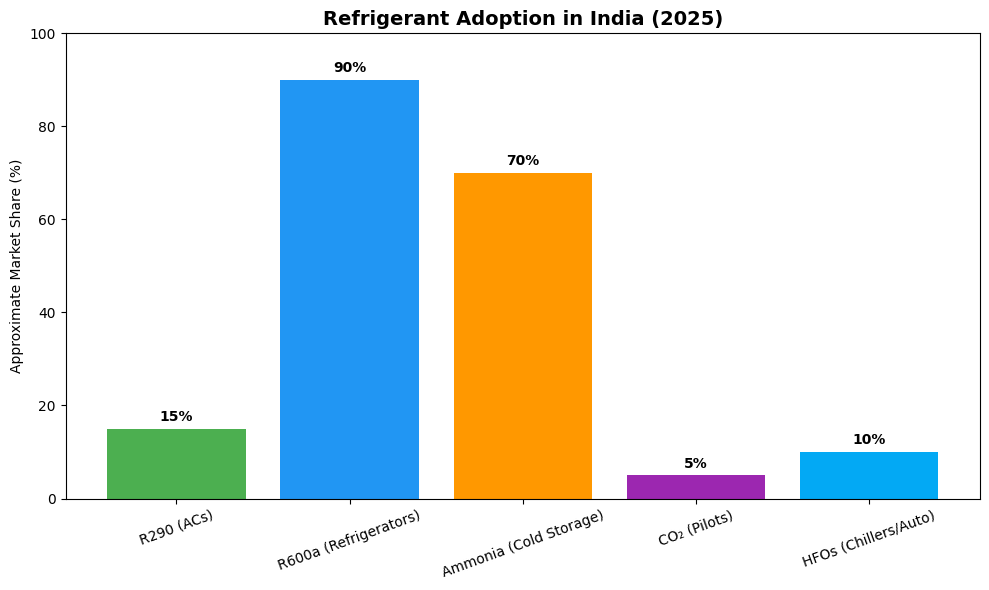

India’s cooling demand will multiply eight times by 2037. For the cold chain, which already accounts for huge energy use, every refrigerant decision matters. Expect rapid momentum:

- R290 adoption in small cold rooms and supermarkets.

- R600a refrigerant dominating plug-in coolers and cabinets.

- HFO refrigerants scaling up in large-scale HVAC and logistics hubs.

- CO₂ and ammonia cementing their role in industrial warehousing.

Closing the Loop

The shift to green refrigerants in India isn’t just about cooling — it’s about business resilience, regulatory readiness, and environmental leadership. With technologies like R290, R600a refrigerant, HFO blends, and natural refrigerants, India is building a cleaner, greener cold chain that meets both global standards and local needs. Discover the future of sustainable cold chain at Refcold 2025