AI-Driven Predictive Maintenance: Elevating Cold Storage Efficiency in India

In India, the cold storage sector is essential to supply chain management, pharmaceutical safety, and food security. With approximately 33,000 units nationwide, the infrastructure is rapidly rising to meet the demands of both foreign trade and the nation’s expanding population. However, some persistent issues, including machinery fails to function, excessive energy expenses, and fragmented infrastructure, continue to hold a stronger position in terms of operational effectiveness and profitability.

AI-powered predictive maintenance has emerged as a game-changing solution that will revolutionize the refrigeration industry and automate supply chain and warehouse management.

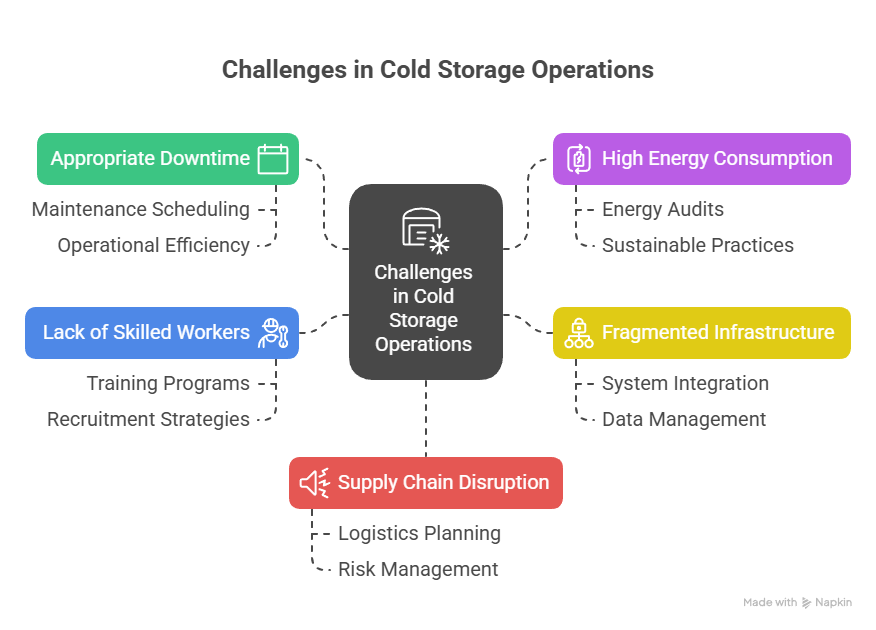

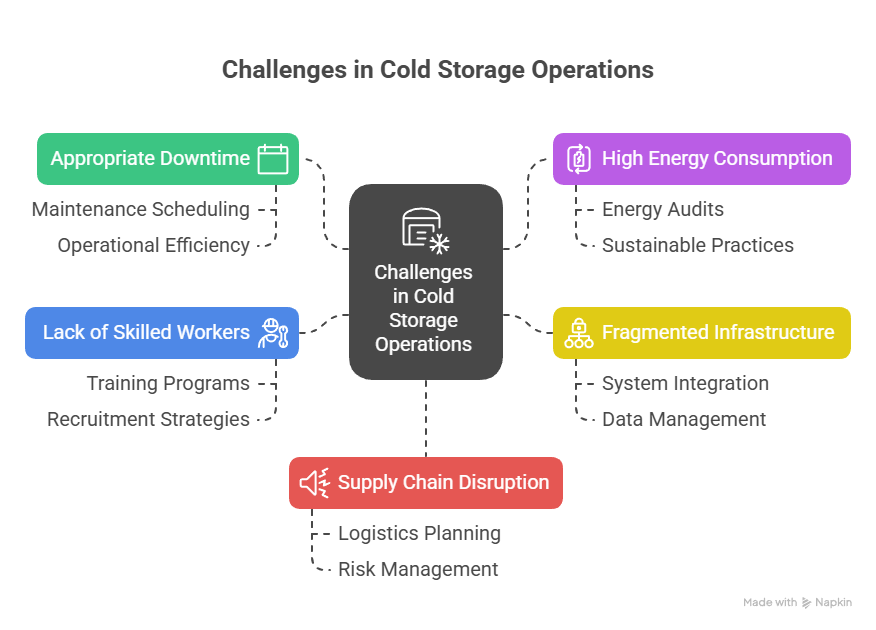

Persistent Challenges in Cold Storage Operations

With the massive increase in growth, Indian cold storage industries yet face certain operational issues:

- Appropriate Downtime: The foundation of any cold storage facility is the refrigeration system. Significant product loss could result from an unanticipated failure, particularly when it comes to temperature-sensitive products like dairy, medications, and fresh fruits and vegetables. There is a chance of loss for every minute that refrigeration equipment in a cold storage facility is not operating. Reliability is therefore essential.

- High Energy Consumption: The energy consumption of a refrigeration system is notably high. Inefficiency in energy consumption or flaws unknown till now might be pushing energy usage exorbitantly high, leading to large operational costs and hence intoxing its sustainability goals. Energy is the most recurring expense for the majority of cold storage operations.

- Fragmented Infrastructure: The majority of India’s tiny cold storage facilities are privately held, and standardized procedures are not widely accepted. This plurality makes it difficult to scale operations or embrace technology and prevents advanced automation and best practices for maintenance.

- Lack of Skilled Workers: Modern refrigeration and automation systems demand a unique set of abilities and knowledge to operate and maintain. Numerous rural facilities lack qualified personnel to fix equipment, which can lead to delays in maintenance, inadvertent damage to the equipment, or even equipment failure.

- Supply Chain Disruption: Delays, product deterioration, and missed business opportunities can result from a cold facility storage failure that jeopardizes the entire supply chain. Modern solutions for those sized-down disruptions would be developed in an industry where temperature and time constraints are crucial.

The Role of AI-Driven Predictive Maintenance

To monitor equipment health and anticipate breakdowns before they happen, the industry is increasingly relying on AI-driven predictive maintenance that uses real-time data, machine learning, and Internet of Things sensors.

Predictive maintenance: what is it?

- Predictive maintenance uses artificial intelligence (AI) to analyze equipment data and forecast when maintenance is required, in contrast to reactive maintenance, which fixes issues after they arise, or preventive maintenance, which follows a set schedule.

- This method prolongs the useful life of vital assets and reduces downtime and related expenses.

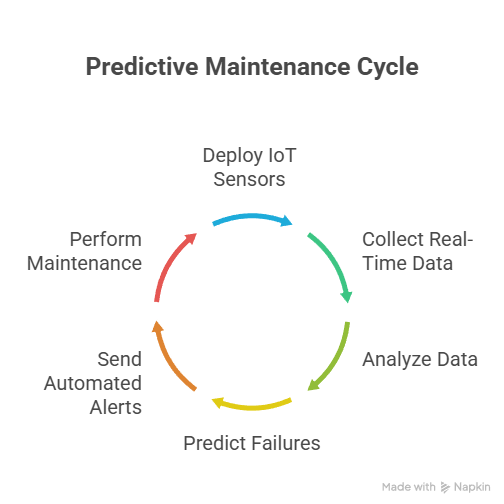

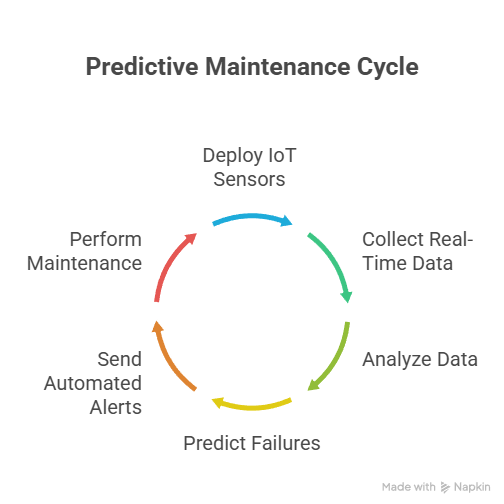

How Predictive Maintenance Works:

- IoT Sensors: Continuous data generation is produced by in-class cold storage equipped with sensors for temperature, humidity, vibrations, and refrigeration unit energy consumption.

- Data analytics and machine learning: AI-powered platforms are designed to process data produced by Internet of Things sensors. For maintenance staff to handle problems before they worsen, machine learning algorithms identify an underlying pattern in superfluous detected irregularities and predict possible failure, often weeks in advance.

- Automated Alerts: The system automatically alerts the maintenance crew when it detects a threat, allowing them to take targeted action and avoid unscheduled downtime. Even organizations with underequipped technical personnel can react quickly and effectively thanks to automated notifications.

Tangible Benefits for Cold Storage Facilities

Adopting AI-driven predictive maintenance delivers measurable results:

- Decreased Downtime: Businesses using predictive maintenance saw up to 30% fewer unscheduled outages, preserving the freshness of their products and preventing damage to their staggered supply chains.

- Improved Warehouse Automation: To ensure that automated conveyors, forklifts, and storage racks operate well in tandem with cooling units, predictive maintenance systems improve coordination with warehouse automation.

- Empowering the Workforce: AI-powered dashboards and warnings streamline maintenance management, enabling technicians to focus on higher-value tasks and enabling less-experienced operators to confidently handle complex procedures.

- Regulatory Compliance: By guaranteeing that equipment is kept within specified operating parameters and providing thorough, detailed records when needed for audits, predictive maintenance makes it easier to comply with stringent regulatory requirements pertaining to temperature control and product safety.

- Energy Efficiency: AI can help facilities reduce their energy expenses by 15% to 20% by detecting energy leaks or optimizing refrigeration cycles. This would increase revenue and incorporate sustainability into reducing the facility’s carbon footprint.

The Future of Cold Storage: Smarter, Greener, and More Reliable

- AI-powered predictive maintenance solutions may soon become the norm in this field due to the growing need for cold storage in India due to the country’s pharmaceutical, food export, and e-commerce industries. These kinds of services are now accessible to warehouses of all sizes, from massive urban warehouses to comparatively smaller ones in remote rural areas, thanks to cloud platforms.

- Optimized refrigeration will directly result in lower operating costs while also assisting India in meeting its sustainability targets of lower energy use and carbon emissions.

- By providing visibility at the end-to-end level, an integrated supply chain management system ensures that each link in the cold chain is tracked and optimized for optimal performance.

Future cold storage activities will not have a carbon footprint, which is a wise and environmentally friendly move. The sector gains more from waste reduction, operational efficiency, and disruption resilience as more facilities implement AI-driven predictive maintenance.

To experience the latest advancements in predictive maintenance, refrigeration, and warehouse automation, register now for Recold India 2025.